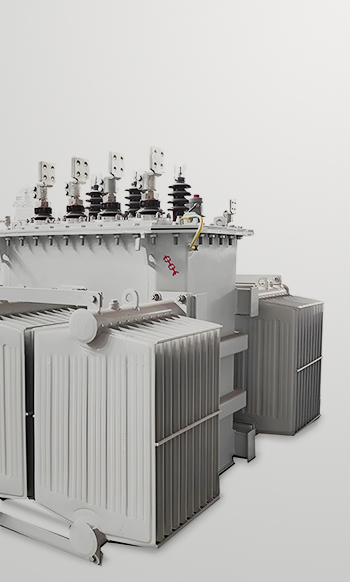

Three Phase Oil Immersed 3D Distribution Transformer

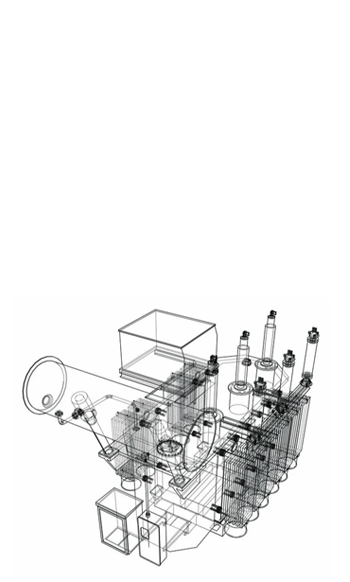

3 Dimension (3D) Wound Cores” are made from three identical single-core frames of trapezoidal silicon steel tape, wound into a compact triangular structure that eliminates air gaps. This innovative design ensures uniform flux flow, reduces total core weight, lowers no-load loss by 20-25%, and decreases excitation current by 50%, significantly minimizing reactive loss and improving the transformer’s power factor (Cos-phi).

- Description

- Additional information

- Reviews (1)

- GENERAL SPECIFICATIONS

- Store Policies

- Inquiries

Description

3 Dimension (3D) Wound Cores” are made from three identical single-core frames of trapezoidal silicon steel tape, wound into a compact triangular structure that eliminates air gaps. This innovative design ensures uniform flux flow, reduces total core weight, lowers no-load loss by 20-25%, and decreases excitation current by 50%, significantly minimizing reactive loss and improving the transformer’s power factor (Cos-phi).

Three Phase Oil Immersed Amorphous Alloy Core Distribution Transformer

| Capacity | Approximated Dimension (mm) | No Load Losses (P 0) | Efficiency 100% | Impedance at 750 C | Transformer Oil Volume | Transformer Total Weight Approx | ||

|---|---|---|---|---|---|---|---|---|

| KVA | Length | Width | Height | Watt | % | % | Liters | kgs |

| 315 | 1285 | 1185 | 1300 | 800 | 98.53 | 4.0 | 280 | 1125 |

| 400 | 1330 | 1250 | 1325 | 960 | 98.63 | 4.0 | 335 | 1380 |

| 500 | 1440 | 1380 | 1390 | 1150 | 98.69 | 4.0 | 405 | 1685 |

| 630 | 1445 | 1385 | 1480 | 1350 | 98.77 | 4.0 | 455 | 1920 |

| 800 | 1655 | 1635 | 1510 | 1400 | 98.53 | 6.0 | 555 | 2285 |

| 1000 | 1740 | 1740 | 1610 | 1600 | 98.61 | 6.0 | 650 | 2680 |

| 1250 | 1745 | 1745 | 1760 | 1850 | 98.71 | 6.0 | 770 | 3135 |

| 1500 | 1845 | 1865 | 1660 | 2050 | 98.68 | 6.0 | 875 | 3740 |

| 1600 | 1865 | 1900 | 1685 | 2350 | 98.68 | 6.0 | 925 | 3935 |

| 2000 | 1880 | 1905 | 1860 | 2650 | 98.76 | 6.0 | 1110 | 4570 |

| 2500 | 2170 | 2130 | 1910 | 3000 | 98.87 | 7.0 | 1175 | 5415 |

| 3000 | 2780 | 2480 | 1990 | 3800 | 98.79 | 7.0 | 1380 | 6380 |

Note

- For spesification above 4000 kVA, Please refer to our large distribution transformer brochure

- The Above is our standard specifications. For special request, please contact our sales engineer

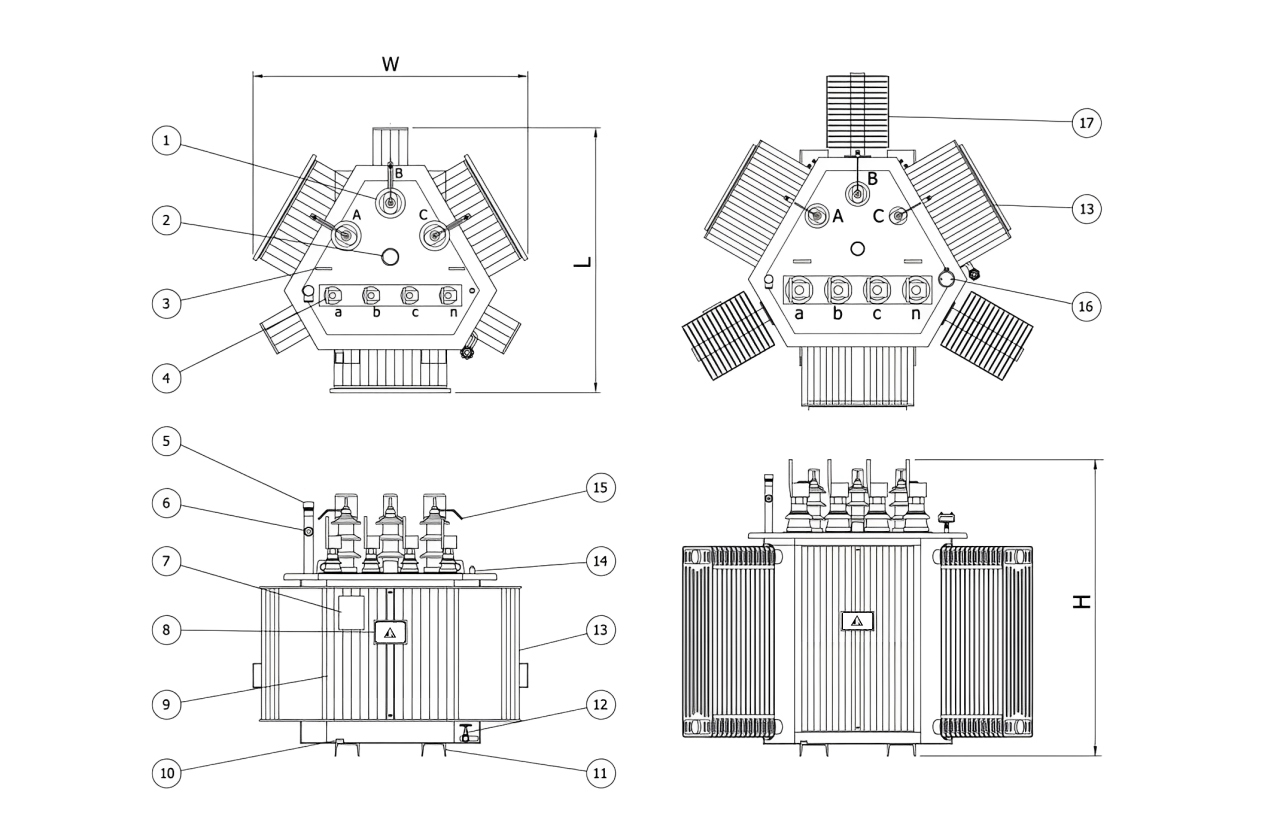

| No | Items Sparepart | No | Items Sparepart | No | Items Sparepart |

|---|---|---|---|---|---|

| 1 | HV Bushing with insulation CAP | 8 | Capacity Plate | 15 | Arching horn |

| 2 | OFF-LOAD Tap Changer | 9 | Trade Mark | 16 | Stick Type Oil Thermometer With Contact |

| 3 | Lifting eyes for Untanking/Tanking Assembly | 10 | Earth Terminal | 17 | Radiator Fin |

| 4 | LV Bhusing | 11 | Foundation | ||

| 5 | Pressure Relief Valve | 12 | Oil Drain Valve with Plug | ||

| 6 | Oil Level Gauge | 13 | Corrugates FIN | ||

| 7 | Name Plate | 14 | Thermometer Pocket |

Additional information

| Weight | 1050 kg |

|---|---|

| Dimensions | 120 × 770 × 1310 cm |

| Capacity (kVa) | 200kVa, 250kVa, 315kVa, 400kVa, 500kVa, 630kVa, 800kVa, 1000kVa, 1250kVa, 1600kVa, 2000kVa, 2500kVa, 3000kVa, 3150kVa, 3500kVa, 4000kVa |

Oil Immersed Distribution Transformer

| Parameter | Minimal | Maximal |

|---|---|---|

| Rated Power (Capacity) | 10 kVA | 4000 kVA |

| Primary Voltage | 6 kV | 33 kV |

| Secondary Voltage | 400 V | 11 kV |

| Frequency | 50 Hz | 60 Hz |

| Cooling Type | ONAN (Oil Natural Air Natural) | ONAF (Oil Natural Air Forced) |

| Efficiency | ≥ 97% | ≥ 99% |

| Impulse Voltage (BIL) | 75 kV | 170 kV |

| Noise Level | ≥ 55 dB | ≥ 65 dB |

| Insulation Class | A | A |

| Ambient Temperature | -10°C | +45°C |

| Humidity Tolerance | 90% | 95% |

| Component | ||

| Core Material | Silicon Steel | Amorphous Alloy |

| Winding Material | Aluminum | Copper |

| Oil Type | Mineral Oil | Synthetic Ester Oil |

| Tap Changer | Off-load (5 Steps) | On-load (±10%) |

| Cooling System | Natural Oil Cooling | Oil Cooling with Forced Air |

General Inquiries

There are no inquiries yet.

Joe Doe –

Awesome!