Industrial Automation & Control

Industrial automation and control systems are designed to optimize energy use,

improve operational efficiency, and enhance safety in industrial environments.

By integrating Artificial Intelligence (AI), Internet of Things (IoT), and real-time monitoring systems, industries can reduce downtime, minimize energy waste, and maximize productivity.

To create a highly efficient industrialautomation Solutionscontrol system, the following components are implemented:

The key components include:

Programmable Logic Controllers (PLCs)

- PLCs control machinery and industrial processes automatically.

- They execute programmed logic to manage equipment operations.

- PLCs can be connected to sensors and actuators for real-time adjustments.

Supervisory Control and Data Acquisition (SCADA)

- SCADA systems provide real-time monitoring and control over industrial electrical systems.

- Enables remote operation and predictive maintenance.

- Helps in detecting faults before they cause operational failures.

Intelligent Switchgear

- Equipped with sensors and digital interfaces for remote monitoring.

- Capable of predictive maintenance, reducing downtime.

- Ensures safe power distribution in industrial settings.

Industrial Automation & Control

Industrial automation and control systems are revolutionizing industries by increasing efficiency, improving energy management, and reducing downtime. With AI-driven automation, real-time monitoring, and predictive analytics, businesses can optimize production, lower operational costs, and achieve sustainability goals.

Industrial Automation & Control

Implementation

Integration of Cloud-Based Power Monitoring:

Centralized monitoring of multiple industrial sites through the cloud. and AI-powered analytics for real-time optimization.

- Real-time monitoring and control of the entire distribution network.

- AI-driven analytics for predictive maintenance and fault detection.

- Remote operation capabilities for increased efficiency.

Centralized monitoring of multiple industrial sites through the cloud. and AI-powered analytics for real-time optimization.

- Ensures consistent power supply and load balancing in industrial zones.

- Minimizes fluctuations that could disrupt operations.

- Protects automation networks from cyber threats.

- Ensures secure remote access and data integrity.

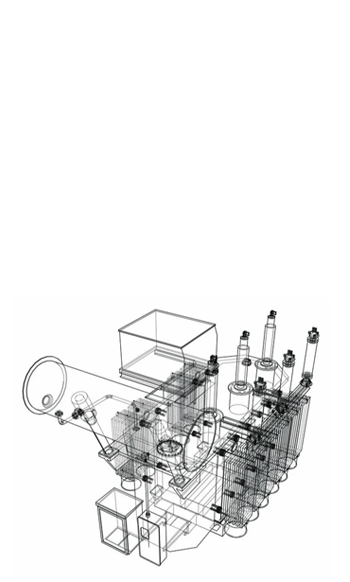

Solution Architecture:

Solution Architecture

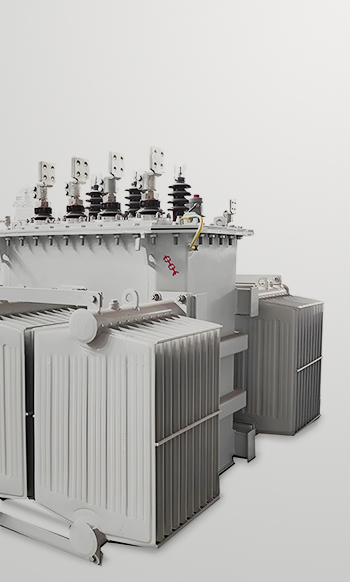

Connected Products

- High-efficiency transformers

- Medium-voltage and low-voltage switchgear

- Ring Main Units (RMU)

Edge Control:

AI-based predictive maintenance, cloud-powered load management, remote fault detection.Connected Products:

AI-driven energy optimization, real-time industrial performance tracking, predictive failure analysis.PT. GOLDEN TRIANGLE ELEKTRIK

Core Skills

We excel in engineering, manufacturing, and innovation, delivering high-quality power solutions that enhance efficiency, reliability, and sustainability.

Manufacturing Industry

We advance in designing and producing high-quality power solutions, and sustainability in every product.

Smart Grid & Automation

Our intelligent power solutions enhance grid stability, automation, and energy management for modern infrastructure.

Green Power

We develop eco-friendly and sustainable power technologies to support the transition to cleaner energy.

Power Distribution

Our comprehensive solutions ensure seamless power transmission and distribution for industrial and commercial applications.

Research & Innovation

Continuous investment in R&D and cutting-edge technology drives product improvement and industry advancements.

Quality & Safety Assurance

Committed to the highest industry standards, we prioritize safety, durability, and performance in all our products.